Polyurethane systems are one of the most used materials for buildings insulation due to their excellent properties. Their structure guarantees air tightness, impermeability, the absence of joints as well as a low thermal conductivity, which allows buildings to have a great thermal behavior and makes them more energy efficient.

Synthesia Technology is a manufacturer and distributor of polyurethane systems for building and industry. The greatest application of these systems is through projection. The result is known as sprayed polyurethane or sprayed polyurethane foam.

Origin of sprayed polyurethane foam: how is it obtained?

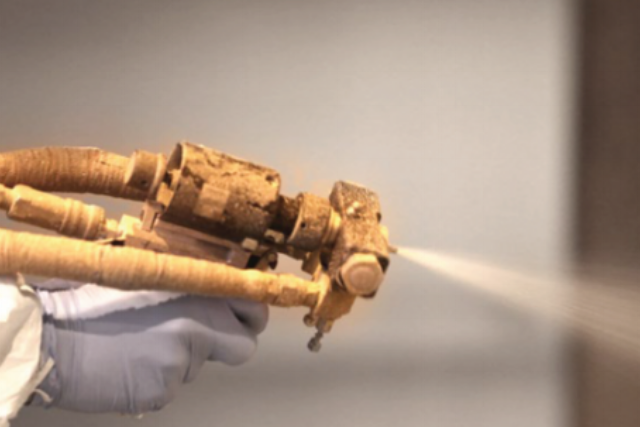

Rigid polyurethane foam is obtained when two chemical products, a diisocyanate and a polyol, are mixed in the presence of suitable catalyzers and activators. In the application of rigid spray foam for thermal insulation in the building sector, the mixing takes place in a small cavity located in the spray gun.

Once the components are mixed, the heat released during the reaction is used to vaporize the expansion agent, which is the cause of the transformation of the mixture into foam with an approximate volume of 30 times the volume of the components in liquid state.

It is important to know how to correctly apply sprayed polyurethane foam, considering a series of factors that range from weather conditions and the adjustments of the equipment to the types and methods of the applications.

In this video (in Spanish), you can see in detail how rigid polyurethane foam is formed from these two components:

Properties of sprayed polyurethane foam

Thermal properties

This material offers a great resistance against the effects of the passage of time and has a long useful life, without deteriorating for more than 50 years.

Rigid sprayed polyurethane foam is the most efficient insulating material, since a minimum thickness is required to insulate the same surface as other insulating materials. This good thermal behavior in relation to thickness supposes an economic advantage, since no useful surface of the building is wasted.

The combination of thermal and economic advantages has been one of the main causes of market development of sprayed polyurethane foam.

Waterproof properties

With a continuous coating such as the closed-cell sprayed polyurethane foam, rendering is not necessary as the material itself meets waterproofing requirements. This supposes both an economic and space advantage, since the necessary thickness is smaller.

Regarding humidity, in most cases sprayed polyurethane foam guarantees the absence of interstitial condensation, due to the values regarding humidity and its density. This feature allows the transpiration of the enclosure, which avoids pathologies related to indoor healthiness and, at the same time, guarantees the durability of the building.

Airtightness properties

An optimal insulation system must provide both thermal insulation and a good behavior against air. In short, it must guarantee the airtightness of the building.

Airtightness is one of the concepts around which passive houses revolve, allowing savings of up to 80% compared to a traditional building.

Sprayed polyurethane foam is a continuous insulation: this continuity forms the barrier against air that allows the envelope of the building to have an adequate level of airtightness.

Sprayed polyurethane foam systems with insulating function

As we have pointed out above, Synthesia Technology is a manufacturer and distributor of polyurethane systems for building and industry.

In the case of sprayed polyurethane foam, our polyurethane systems applied to buildings are based on three functions: thermal insulation, acoustic insulation and anti-radon barriers.

Sprayed polyurethane foam as thermal insulation

It can be stated that sprayed polyurethane foam is booming, and this is largely due to its functions as thermal insulator. Below, some examples of applications of our sprayed polyurethane systems with thermal insulation functions:

Sprayed polyurethane foam as acoustic insulation

We have a range of sprayed polyurethane systems that, in addition to the function of thermal insulation, have excellent acoustic characteristics. You can read more about it in:

Sprayed polyurethane foam as an anti-radon barrier

Our newest polyurethane system combines the function of thermal insulation with that of anti-radon barrier. The superinsulation ECO spray foam system is presented as an efficient solution against the danger of radon gas in buildings.

This anti-radon barrier is optimal both in new construction and already built buildings.

The examples mentioned above are just some of our polyurethane systems designed for buildings. We have a wide variety and a specific line of polyurethane for industrial applications.

Would you like to know more about Synthesia Technology’s sprayed polyurethane systems? Do not hesitate to contact us.