Floors are some of the elements of an envelope that must be taken into account when it comes to insulating acoustically a room, which is usually delimited by two of them: the upper and the lower floor. Sprayed polyurethane systems are an optimal material to insulate floors and slabs against airborne or impact noise, both in renovations and new works.

Phono Spray S-907 is a sprayed polyurethane system designed to improve the acoustic insulation of buildings, especially against impact noise affecting floors and slabs, and it complies with current noise protection regulations.

Phono Spray S-907 polyurethane system

Phono Spray S-907 is a thermo-acoustic polyurethane system of two components, polyol and isocyanate, which contains no foaming agents that may damage the ozone layer. The system is applied by "in situ" projection, obtaining open-cell foam of medium density (55-65 kg/m3). Due to its porosity and elasticity, it is an ideal material to insulate floors or slabs against impact noise.

It offers many advantages, such as:

- Suppression of thermal bridges.

- Good adhesion to the substrate.

- Ease of mobility, as there is no need to carry or to store bulky products as in the case of other insulation materials.

Application of the Phono Spray S-907 system

This system is applied by casting with high-pressure equipment, equipped with heating, with a mixing ratio of 1:1 in volume. Its main application is the improvement of sound insulation against noise, especially impact noise in horizontal partitions.

The recommended temperature in hoses is 30ºC to 50ºC depending on environmental conditions, and the minimum recommended temperature of the substrate during injection is 5ºC.

The adhesion of the Phono Spray S-907 system is excellent to all the materials used in construction (concrete, ceramics, laminated gypsum, wood, etc.) provided they are clean, dry and free of dust and grease.

Phono Spray S-907 tests

Acoustic insulation tests

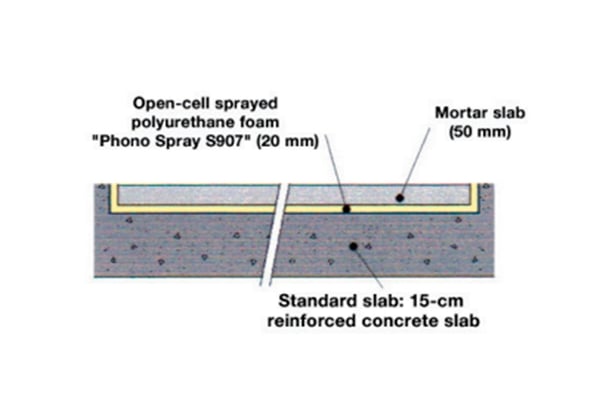

Airborne noise insulation tests have been carried out in accordance with UNE-EN ISO 140-3:1995 and impact noise tests in accordance with UNE-EN ISO 140-6:1999 and UNE-EN ISO 140-8:1998 on a floating floor made of mortar and sprayed with Phono Spray S-907 on standardized concrete slab.

|

Separating element |

∆L (dB) |

Lnw (dB) |

Rw (dBA) |

|

Standard Slab Concrete 15 cm + Phono Spray S-907 2 cm + Mortar 5 cm |

14 |

60 |

56 |

In-situ acoustic insulation tests

|

Separating element |

LnTw (dB) |

|

FORGING + Phono Spray S-907 2 cm + Mortar 5 cm |

<65 |

|

FORGING + Phono Spray S-907 3 cm + Mortar 4 cm |

<65 |

The following video shows the application of the Phono Spray S-907, an optimal solution for floor and slab insulation: