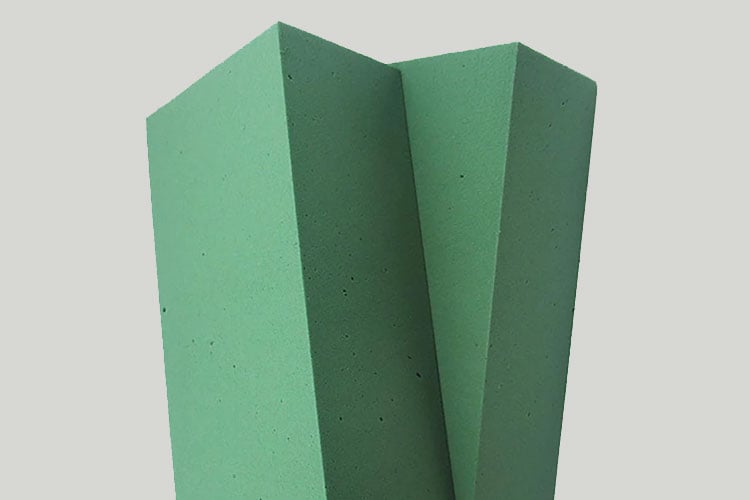

One of the most challenging applications of polyurethane in terms of processing as well as formulation design is the manufacture of floral foam, a rigid, moulded, open-cell, polyurethane foam specially designed for flower (dried and artificial) or natural flower arrangements. After the necessary curing time, it can be easily cut into blocks of the desired size and shape, which will deliver its performance uniformly.

Types of polyurethane foams for floral applications

Rigid polyurethane foam intended for natural flowers has to be soft enough to allow the weak stem of the natural flower to penetrate the polyurethane foam structure, but at the same time elastic enough so that when the stem of the flower is nailed in, it is well gripped and the flower does not come loose.

For flower arrangements with dried or artificial flowers, rigid polyurethane foam provides support, flexibility and easy handling. It can be easily pierced with the stem itself and gives excellent results as a base for plants and flowers that do not need water. This type of foam is ready to use and very versatile.

Type of material for floral applications

At Synthesia we have the product Poliol 7646-M-21 / H-25C, a low density moulded floral foam, designed for natural flowers. Poliol 7645-M-27 / H-25C is a medium density moulded floral foam, which serves as a base for artificial flowers. Likewise, Poliol 7690 / H-25C are floral foam blocks of higher density, for the production of floral plates.

These are systems that, if safety recommendations are taken into account, do not present risks when handled, although it is advisable to avoid contact with eyes and skin.

Polyurethane, a sustainable material

These rigid polyurethane foam products for floral mouldings are free of CFCs, HCFCs and HFCs, so they do not damage the ozone layer or contribute to global warming. Moreover, Polyol 7646-M-21 / H-25C and Polyol 7645-M-27 / H-25C contain only water as a foaming agent.

In addition, polyurethane is a sustainable material, because it generates very few CO2 emissions in its production. It is also recyclable: by reprocessing polyurethane waste, a foam is produced from which new products (insulation, packaging material, etc.) can be made.